Thermoplastic pellets for filaments extrusion

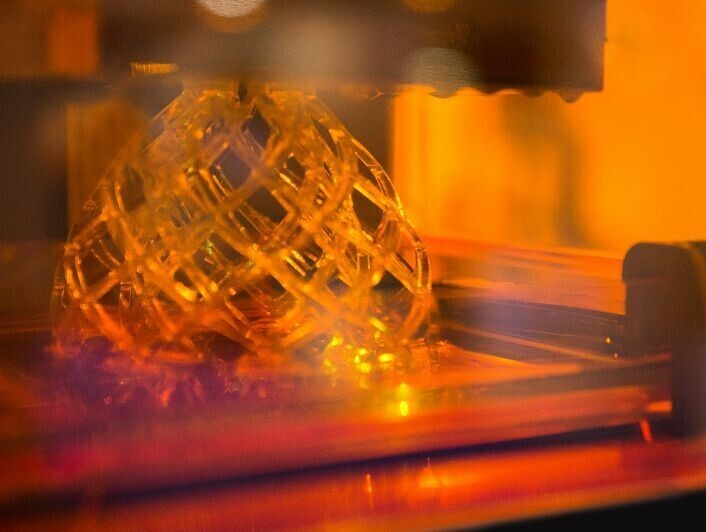

Arkema’s 3D printing solutions include a dedicated range of advanced polymers for filament extrusion printing technologies.

These products are designed for 3D printing highly technical parts requiring extreme performance.

Properties include resistance to high temperatures and harsh chemicals, and outstanding flame and smoke properties. These products enable the production of parts that will be used in some of the most demanding applications in the world and can bring high value to end-users.

Kepstan® PEKK

Kepstan® PEKK (PolyEtherKetoneKetone) is an extreme performance thermoplastic with a highly stable chemical backbone. Its tunable semicrystalline structure offers an outstanding combination of mechanical and thermal strength together with tremendous chemical, and fire resistance.

Kepstan® PEKK grades for filament extrusion offer both ease of printability and the highest physical performance of any thermoplastic material currently available for 3D printing.

Product highlights

- Outstanding high temperature performance

- Inherent flame resistance, low smoke generation, and toxicity

- Excellent chemical resistance

- Outstanding mechanical, wear, and impact properties

- High dielectric strength and good insulating properties

- Easier to print than PEEK - Minimal part warping

- Possible to produce either amorphous or semicrystalline parts

Compatible printing technologies

- FFF

- FDM

More information about Kepstan® PEKK

Kynar® PVDF

Kynar® PVDF (Polyvinylidene fluoride) resins are extremely resistant to harsh chemicals and UV radiation. They are known to be among the most durable polymers in the world. This tough semi-crystalline fluoropolymer, formulatedfor printability, benefits from outstanding Z direction strength and ductility.

Filaments made from Kynar® resins are particularly suitable for early stage prototyping or short run manufacturing. Kynar® PVDF resins are specified for printing chemical processing equipment, fluid transport parts, outdoor exposed elements, or fixtures.

Product highlights

- High continuous use temperature – up to 130°C

- Excellent resistance to a broad range of chemicals

- Non-hygroscopic - does not absorb moisture - no drying needed

- Inherently UV-resistant

- Very good abrasion resistance – similar to nylons

- Low smoke and flame characteristics (base resin is rated V-0)

- Long-term hydrolytic stability

Compatible printing technologies

- FFF

More information about Kynar® PVDF

Pebax® TPE

Polyether block amide copolymers are highly regarded for their lightness, unmatched energy return, and cold temperature durability. This unique polymer offers the highly desirable combination of toughness traditionally associated with polyamides and the flexibility/elasticity more often seen with polyethers/polyesters.

Filaments made from Pebax® resin are particularly well suited for functional prototypes or short run manufacturing. Pebax® elastomers are world renowned in sports, industrial, and footwear applications.

Product highlights

- Easy to print on direct drive printers as well as some Bowden printers

- Excellent layer to layer adhesion (>300% elongation)

- Low energy loss factor across wide temperature range

- High impact resistance, especially at low temperature

Compatible printing technology

- FFF