Act for climate and environment

Every day we act to reduce our consumption of resources such as energy and water by implementing ambitious programs and reducing the emissions linked to our activity. We develop the use of renewable resources and promote the circular economy in order to preserve non-renewable natural resources and protect biodiversity by limiting our emissions into the air, water and soil.

This approach is combined with ambitious targets that aim to reduce energy consumption and emissions into air (greenhouse gases and volatile organic compounds) and to water (chemical oxygen demand).

Reducing our greenhouse gas emissions throughout our value chain

In the face of a climate emergency, it is essential to reduce greenhouse gas emissions.

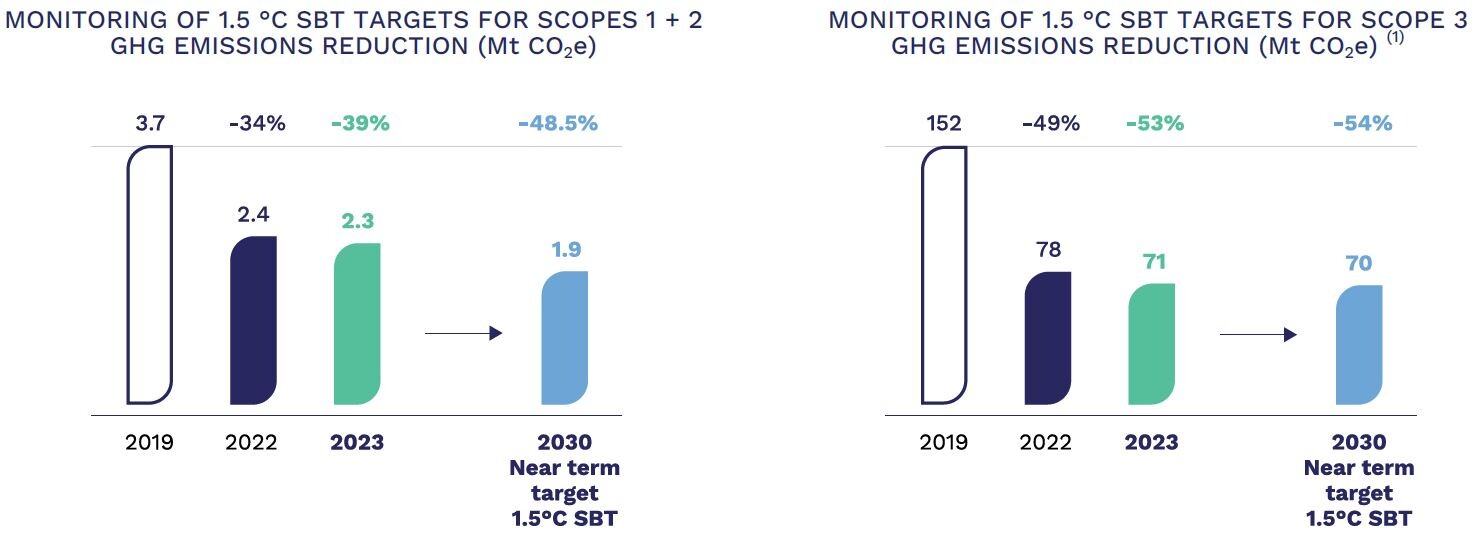

In line with the expectations of the Paris Agreement, which aims to limit global warming to 1.5°C above pre-industrial levels by the end of the century, Arkema strengthened its Climate Plan in May 2023 and set new, more ambitious targets, approved by the organization Science Based Targets initiative (SBTi):

- A 48.5% reduction in its GHG emissions for Scopes 1+2 by 2030 compared with 2019

- A 54% reduction in its GHG emissions for Scope 3 by 2030 compared with 2019

Key objectives between 2019 and 2030:

-

Reducing Scopes 1+2 greenhouse gas emissions by 48.5%

-

Reducing Scope 3 greenhouse gas emissions by 54%

Direct emissions (scope 1) generated by the operations and production processes at our plants; and indirect emissions (scope 2) generated by the electricity and steam purchased for our plants.

Scope 3 includes upstream and downstream activities (purchases of raw materials, goods and services, transformation, use and end-of-life treatment of our products, etc.)

Arkema has been working to reduce its carbon footprint for many years, by continuously improving its production procedures and implementing a determined policy of optimizing energy efficiency.

In concrete terms, the climate plan is implemented with each of our business lines and industrial facilities. The Arkema Energy global program adopted in 2013 is one of the key levers. The energy efficiency of our industrial operations has already improved by 15% compared with 2012, and we aim to increase this gain to 25% by 2030.

Paving the way to Net-Zero by 2050

We have made significant progress in reducing greenhouse gas emissions since 2019.

Our 2030 targets validated by SBTi give us a solid foundation, paving the way to Net-Zero by 2050, which would mean a 90% reduction in emissions across all scopes.

Arkema Energy

The Arkema Energy project aims to improve the Group's energy efficiency. It consists of a structured and consistent approach across the entire industrial perimeter to implement an energy-saving culture at all levels of the company.

Between 2014 and 2020, Arkema Energy projects have resulted in a reduction in consumption of 800 GWH, of which 9 % is related to a reduction in electricity consumption and 91% to a reduction in heat consumption (gas, steam). The corresponding reduction in GHG emissions is 185 kt CO2 eq.

Decarbonizing our energy

Through long-term commitments to purchase renewable electricity and by working with our partners to reduce the carbon footprint of purchased steam, Arkema is working to accelerate the decarbonization of our energy sources. For our own steam production, we are developing the use of alternative fuels and the electrification of our boilers.

Achieving our GHG emission reduction targets also involves moving towards less emissive manufacturing processes and product ranges, as well as strengthening emissions capture and treatment.

Lastly, we are stepping up our efforts to take the climate into account in our investments by setting an internal carbon price of 100 euros per ton of CO2.

Innovation and supplier commitment to decarbonize the value chain

With this new commitment to a 1.5°C trajectory across our value chain, Arkema also intends to reduce its Scope 3 emissions by 46%, reaching 85 million metric tons of CO2 equivalent in 2030, compared with 158 million metric tons emitted in 2019. These emissions take into account all Scope 3 categories. To achieve this goal, Arkema is taking action on the most emissive components, both upstream and downstream.

- Upstream, the carbon footprint of raw materials purchased is the most significant category. Arkema continues to engage in climate dialogue with its suppliers and encourages them to set SBT targets for their scopes 1 and 2 by 2025.

- Downstream, the reduction of activities in the most emissions-intensive applications of fluorinated gases covered by the Kyoto Protocol and the development of new generations of HFOs for high-value-added activities are major levers for reducing Scope 3.

We are also drawing on the strength of our innovation in support of sustainable development, and in particular the "Materials Design and Lightweighting" innovation platform, to develop our product and service offering towards solutions that contribute to reducing greenhouse gas emissions.

Foster circular economy in our plants

To respond to the scarcity of natural resources and the increasing environmental impact of human activities, Arkema develops the circular economy, in particular to recover co-products and ensure proper waste management.

Resources optimization

Our initiatives to reduce the environmental impact of our industrial sites are underpinned by its resource management policy and notably consist in optimizing the use of raw materials, energy and natural resources like water. New manufacturing units are designed to incorporate environmental footprint considerations into the choice of processes and equipment. We also pay a special attention to operating conditions and maintenance and development investments are regularly undertaken to optimize the use of water, energy and raw materials at our plants.

Reusing by-products

The production of our main products sometimes generates co-products that can be used by other businesses.

By-products from the conversion of castor oil into undecanoic amino acid at the Marseille (France) plant are examples of reuse through the Oleris® range, whose bio-based origin is sought after.

Waste management

Arkema helps protect the environment by reducing the amount of waste we produce and recovering it as materials or energy.

- At the Hengshui site in China, similar by-products, along with

crystallized sodium sulfate converted from a sulfuric acid waste

flow, accounted for a total of 69,000 tonnes sold in 2021. - On the Lacq site (France), desulfogypsum from the sulfur residue treatment facility is a nonhazardous waste that is re-used as a material for the manufacture of plasterboard in cement works. In 2021, 12,500 metric tons of desulfogypsum were recycled in this way, thereby avoiding their being sent to landfill.

Water management optimization

To preserve our water resources, we have established measures to limit our consumption and emissions. Water is essential throughout the production process, whether for cooling installations or for steam production, so we must use it wisely.

Water use

Arkema contributes to better access to water for all, and also improves its production practices to minimize its water consumption by:

- Implementing methods for reducing consumption ;

- Using closed circuit cooling systems.

Emissions to water

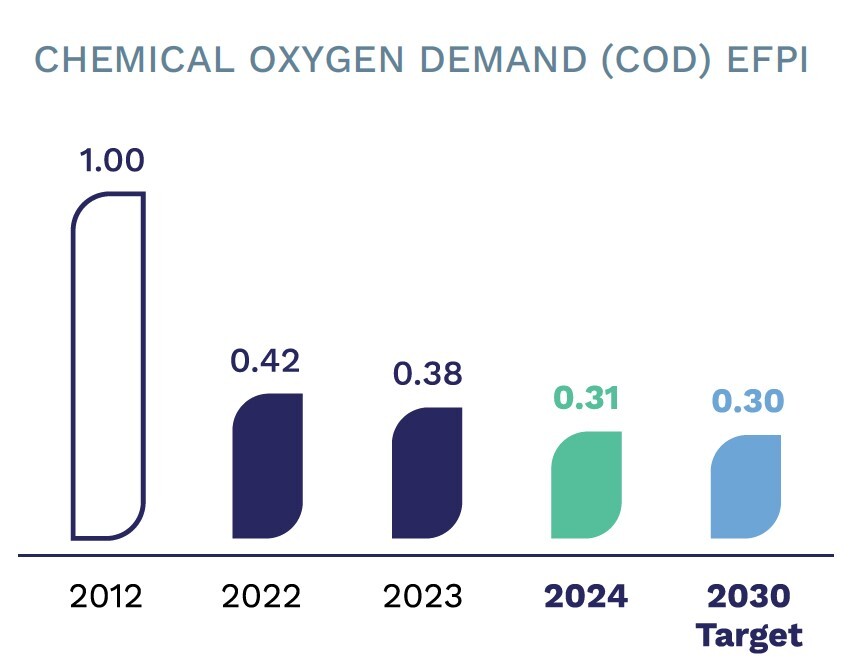

Diminishing its emissions to water also ranks high among the chief environmental objectives of Arkema. We are especially attentive to effluents that could result in high chemical oxygen demand (COD) or contain high levels of suspended solids (SS).

Arkema reduces its COD and high-SS effluent discharge by:

- Installing its production plants in industrial parks equipped with full-scale wastewater treatment plants ;

- Installing physical-chemical and/or biological treatment process units to treat effluents at its more isolated plants ;

- Optimizing the treatments wastewater plants or better controlling water sent in station.

Optim'O

Launched in 2016, the Optim’O program encompasses all water-management activities across the group, and in particular those geared towards consumption reduction, recycling, COD reduction and water-stress scenarios.

Thus, Optim'O aims by 2030 to reduce the Chemical Oxygen Demand (COD) of discharges by 60% in intensity compared to 2012.

Protect biodiversity

Arkema cares about preserving biodiversity and contributes to protecting the world’s fauna and flora by reducing each site’s emissions into air, water and soil.

Emissions into air, water and soil

Arkema seeks to protect flora and fauna from the impacts of its operations. We therefore work every day to reduce emissions into the air and water and the impact on the soil and subsoil at each site.

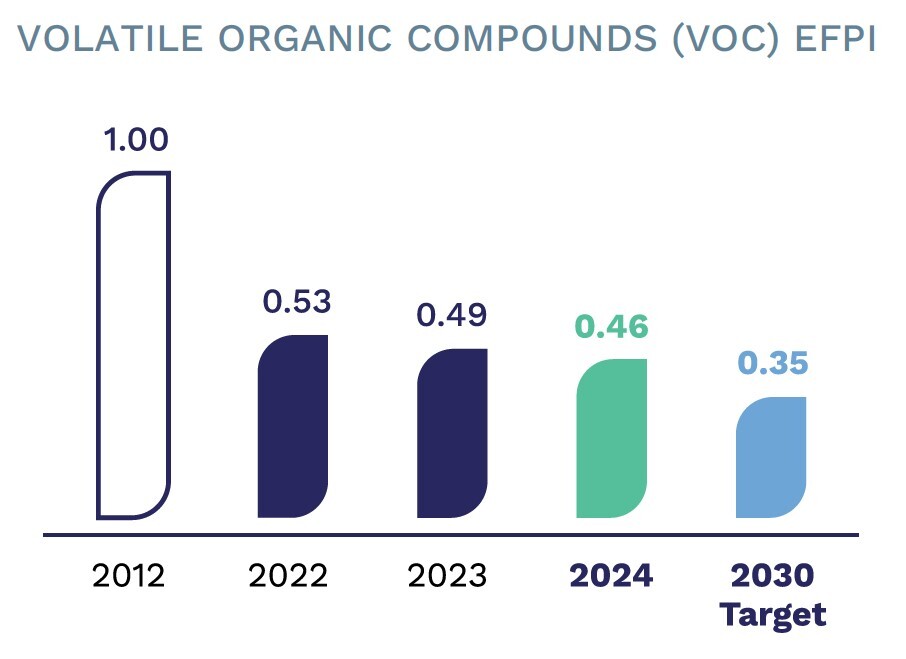

Thus, we reduce the chemical oxygen demand (COD) in the effluent discharged into rivers, thereby preserving the dissolved oxygen that is essential to all aquatic life, and limit emissions of volatile organic compounds (VOCs) into the air and greenhouse gas emissions (GHG).

Thus, by 2030 we aim to:

- reduce VOC emissions by 65 % (vs 2012)

- reduce GHG emissions by 38 % (vs 2015)

- reduce COD emissions by 60 % (vs 2012)

In 2020, ongoing work to update the solvent management plan for the Genay site (France) resulted in a better assessment of VOC emissions, explaining the drop of over 90% in its emissions.

Committed with Act4nature

Arkema has long been committed to reducing the environmental footprint of its production processes. Arkema is working to protect biodiversity and help preserve fauna and flora by reducing its industrial facilities' effluent releases into the air, water and soil.

In 2021, convinced of the importance and urgency of taking biodiversity into account, Arkema has strengthened its initiatives to protect the environment by announcing its commitment to Act4nature International on a global scale.

The Group is therefore reducing its VOC emissions by:

- collecting and treating effluents containing VOCs, particularly with thermal oxidizers or vent scrubbing; and

- carrying out regular campaigns to detect and eliminate VOC leaks.

VOC reduction at the Marseille site (France)

The start-up of a new treatment unit in 2020 enhanced the Marseille site’s existing measures and enabled a 17 % reduction in its VOC emissions.